Medical Devices

Flex Interconnect Technologies has a long history of providing state-of-the-art solutions to our medical device clients. Some of the products we’ve produced include:

- Smart patches that detect concussions

- Invasive endoscopy units

- Glucose monitoring systems

- Disposable medical devices

- Microfluidic controllers

Our production capabilities range from quick-turn prototyping and NPI support to offshore production for high-volume production. We are FDA 820 B certified. All of our assemble products are ISO-13485 certified, with complete traceability to the component level.

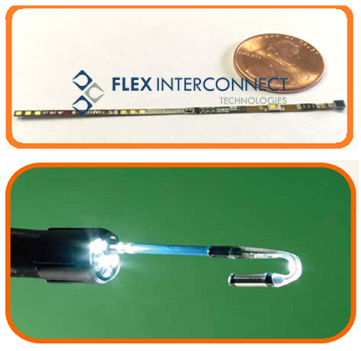

ENDOSCOPE

4 LAYERS, 4 MIL VIA ON 12 MIL PAD, 3/3 MIL SPACING, AND CSP CAMERA PACKAGE

This is a medical application with an extremely narrow circuit. In this case the customer came to us with cracking traces. You can see the narrow bend requirements in the picture and when they bend and unbend over 20 times the flexes were failing them. This is an example where we took a customers flex, redesigned it, chose the right material and made it successful for them.

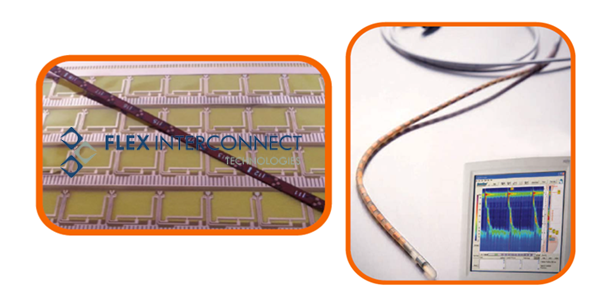

HARNESS FLEX- CATHETER

7 LAYER, 16 “ FLEX, 4/4 MIL LINES AND SPACING WITH A LASER CUT TOLERANCE +/- 2 MILS. THE SENSORS ARE MADE WITH 0.4 MICRON COPPER.

We’ve been building this harness flex and sensor for a large Medical Device customer for the past 15 years. Where other shops wouldn’t touch these very thin copper requirements, we raised our hands to give it a shot and succeeded.